Leading Edge Technology Investment

Newbury Electronics invests in leading edge technology to deliver benefits to its PCB customers.

* Improved accuracy

* Reduction in material costs

* Rapid set-up and changeover

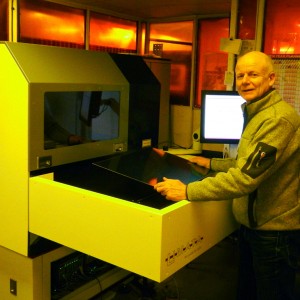

Newbury Electronics, one of the country's leading designers and manufacturers of printed circuit boards, has installed a laser direct imaging system that will deliver significant benefits to its clients. The new machine, a UV-P300 LDI, is manufactured by Limata, and uses the latest in laser technology to produce far more technically demanding printed circuit boards than could be achieved using the more traditional photo lithographic techniques. It is the first machine of this type to be installed in the country.

Philip King, Managing Director at Newbury Electronics, said; "This is a significant investment for our company and one that we believe will make a real difference to both the quality of our products and the efficiency of our service. The old saying 'time is money' is very true in the highly competitive field of manufacturing and being able to deliver the highest quality PCB from here in the UK, with reduced delivery times, gives both us and our clients a real advantage in the market place."

The new machine, which has been installed at the company's manufacturing site in Newbury, uses an innovative eight laser sources that deliver a three-fold resolution improvement over more traditional photographic based systems. Images are printed directly on to circuit board material without the need to produce costly and fragile photographic master tooling. Problems associated with temperature and humidity instability of photography are eliminated. With a 25 micron laser spot, the high-resolution system installed at provides perfect images on the company’s standard plating and resist masks.

Other benefits of the system are the provision of automatic fiducial camera registration which overcomes the problem of poorly registered images, the auto focus capabilities which allows the system to cope with different thickness of material and rapid job change-over without expensive tooling. The laser system is long life and fault tolerant. In the unlikely event of a laser failure, production continues with the remaining laser sources.

Background

Newbury Electronics Ltd started trading 1956. A management buyout took place in 1987 and Philip King took on his role of Managing Director in 2011. The company offers a full electronic design, PCB design and layout service alongside PCB manufacture and assembly in Newbury, West Berkshire. It employs 65 staff and is dedicated to small and medium batch PCB assembly, specialising in electronic design and manufacture incorporating SMD, SMT, surface mount, BGA, through hole, box build, soldering, test, & rework. Customers can select from electronics design and CAD layout through to printed circuit board design and fabrication, assembly and test, and the company is happy to undertake single, bespoke projects through to the design and supply of manufacture lots of up to 10,000 pcs on its automated SMD assembly lines.

As a contract electronic manufacturer (CEM), each year, the company produces in excess of over 15,000 different PCB designs for its clients, who benefit from the economies of scale built from the volume of orders processed.