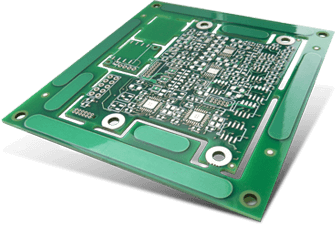

PCB fabrication services

We manufacture bare PCBs to your exact design needs and specifications. Simply request a quote for a fast turnaround of as little as 24 hours.

We manufacture bare PCBs to your exact design needs and specifications. Simply request a quote for a fast turnaround of as little as 24 hours.

Newbury Electronics specialises in fabricating high-quality, competitively priced printed circuit boards for a range of clients. Working with our sister company, PCB Train, our PCB fabrication service delivers more different types of printed circuit boards per year than any other UK PCB manufacturer and relies on the talents of many experienced engineers to meet customers’ demands.

With over 6 decades in the PCB manufacturing industry, we’re proud to offer huge flexibility over order scales and manufacture everything from PCB prototypes and small-batch PCBs to multi-layer PCBs, flexible PCBs and high-volume orders of more than 10,000. Thanks to our understanding of bare PCB design and fabrication, no order quantity is too small and no turnaround time is too fast. We are also renowned for our low cost, reliable deliveries, high-quality PCBs and excellent technical support and are the only UK PCB fabrication company that uses a completely digital PCB manufacturing process. We have full control over all our production processes, allowing us to rectify any issues, guarantee PCB quality and ensure that we can get your circuit boards to you exactly when you need them.

We manufacture both locally in the UK and overseas. Our pre-production, small and medium batch PCBs are manufactured in our UK facility. For large production batches, we supply PCBs manufactured by our carefully selected international partners. However, regardless of where they are manufactured, our entire PCB fabrication process is overseen and managed by Newbury Electronics, so you can trust that only one tooling charge is applied.

Once complete, each product is quality checked in the UK and our deliveries are consistently completed on schedule. See our guide below for a complete overview of how PCBs are made at Newbury Electronics.

PCB Train exists to supply PCBs you can trust. Our UK plant is dedicated to manufacturing high-quality PCBs in small and medium batches, using the very best production plant and design techniques available. This rapid PCB service is available for circuit boards with up to 12 layers and comes with a choice of thicknesses, laminate specifications and finishes.

If you’re interested in acquiring a prototype PCB before setting up a full production run, you can take advantage of the PCB Train Express service. 2-layer PCBs are available via PCB Train Express in around 24 hours whereas 4-layer PCBs can be completed in around 48 hours. Please read about our 1-Day Turnaround Express Service for PCB Fabrication in more depth before placing your order. You can find also find out more about our low-volume PCB manufacturing services on the PCB Train website or start your online PCB quote today.

Newbury Electronics is one of only a very few PCB manufacturers to employ the most up-to-date digital manufacturing process where all imaging is direct from digital data, and no intermediate photographic film tooling is necessary. This gives superior registration (both solder resist to pad and drill to copper land) and permits a finer track and gap capability. Additionally, we are also unique in that we oversee every aspect of our PCB fabrication services from our UK factory, with only an occasional need to outsource elements of our work. Clients choose us as their PCB manufacturer because we can guarantee three things: high-quality, competitive prices and excellent customer service. Contact us for a PCB quote today.

We’re well known for being efficient and flexible in terms of delivery lead times. These can range from a mere 24 hours up to 6 weeks according to your needs.

We work with high quality base materials such as FR4, Polyimide and PTFE all available in in a wide variety of specifications, thicknesses and copper weights.

We offer a wide range of solder resist and legend colours. Finishes available are immersion silver, immersion gold over electroless nickel, Hot Air Solder Level, both lead-free and leaded.

All our technology and machinery is state-of-the-art. Front-end tooling is performed with the latest CADCAM software tools, with complete design rule checking. We use modern manufacturing technology, such as laser direct imaging, whereby the intermediate photographic process is eliminated. Each FR4 panel is laser scanned to image the tracking pattern. PCBs are drilled on automatic load and unload drilling machines. Plating and etching are processed on automatic lines to minimise manual handling. Legends are printed with digital ink-jet machines. Electrical tests are performed by automated machines.

Newbury Electronics are quality approved to UL and ISO 9001. Bare PCB production is electrically tested and automatically optically inspected. We use a variety of quality control methods including statistical process control, micro-sections, X-ray, chemical analysis, time domain reflectometry, and digital microscopy.

| View our Quality approvals. |

Our PCB fabrication and manufacturing customers could be anyone who requires a reliable supplier of PCBs. We attract those who appreciate experienced electronic manufacturing and a high quality end product. Our customers may be end users, development engineers, researchers, or contract manufacturers. Our clients also value local sourcing, confidentiality and good communications. We are happy to provide this. No quantity is too small and no delivery is ever too fast for us.

For standard construction PCBs, we just need a brief description of the nature of your PCB together with Gerber and CNC drill file data. For more complex requirements, we require detailed material specifications, and layer build-up drawings showing the exact construction of your multi-layer PCB.

| Please submit a PCB fabrication quote or email us. |