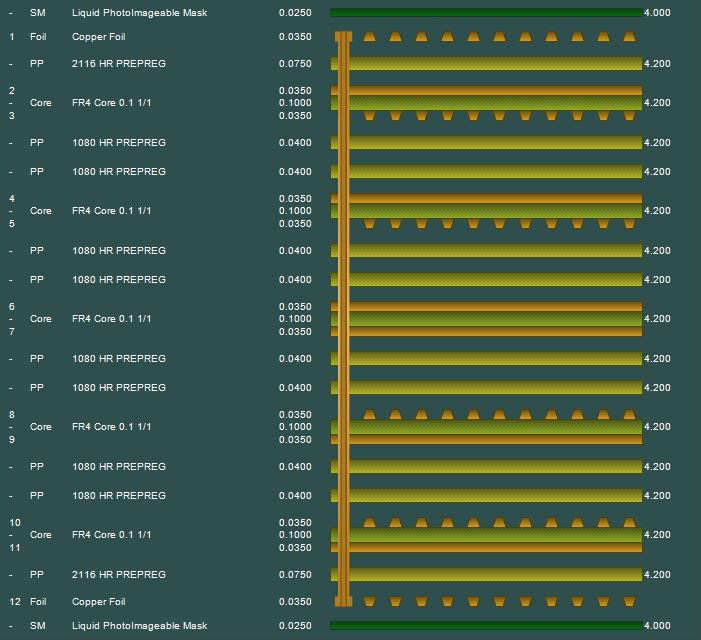

Multilayer PCB Builds

A multilayer PCB is a printed circuit board that has more than 2 layers of conductive material. Even though their design is generally more complex than either single-sided or double-sided PCBs, multilayer circuit boards are tremendously popular with manufacturers of electronic devices. This is due to their smaller size, increased capacity and high speed of operation.

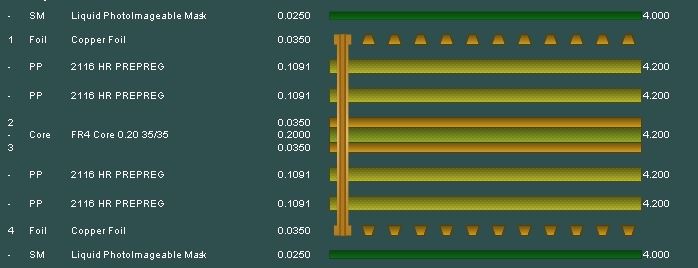

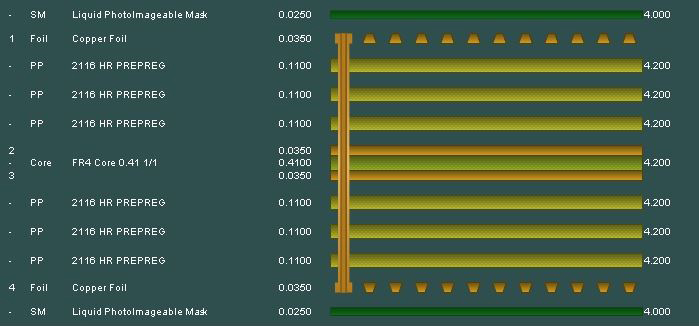

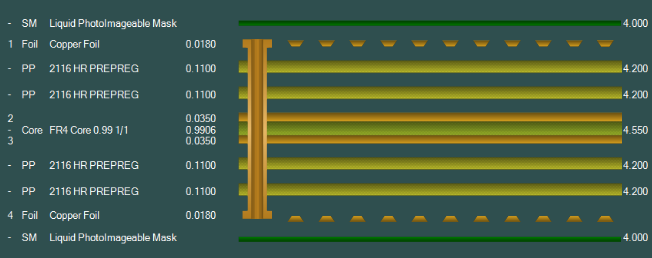

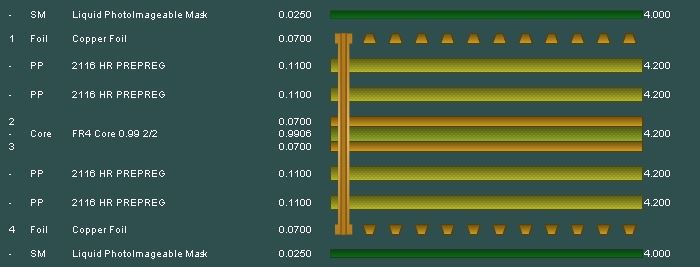

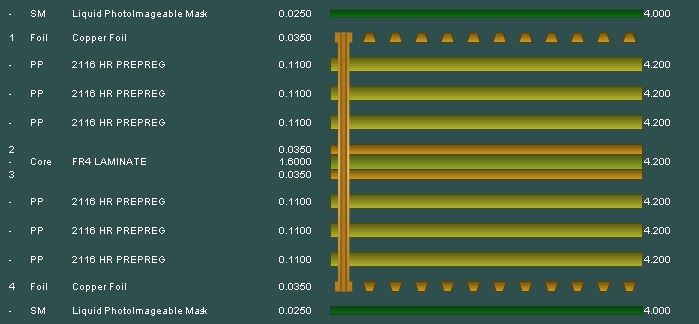

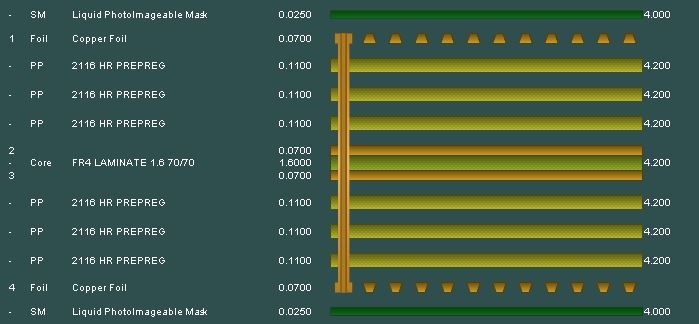

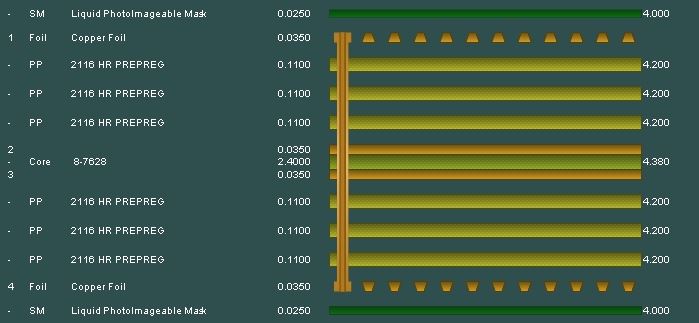

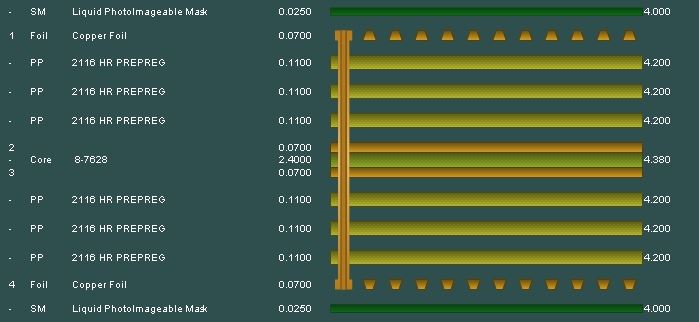

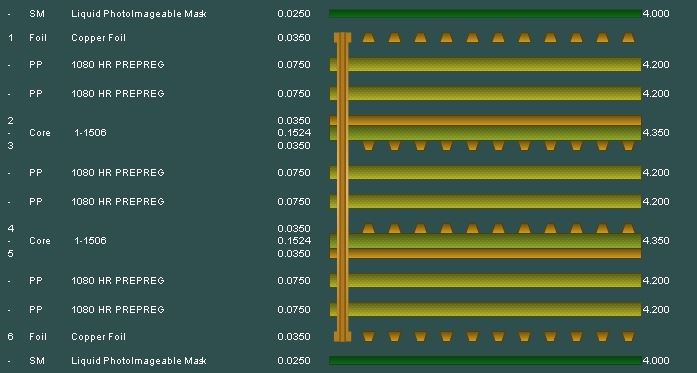

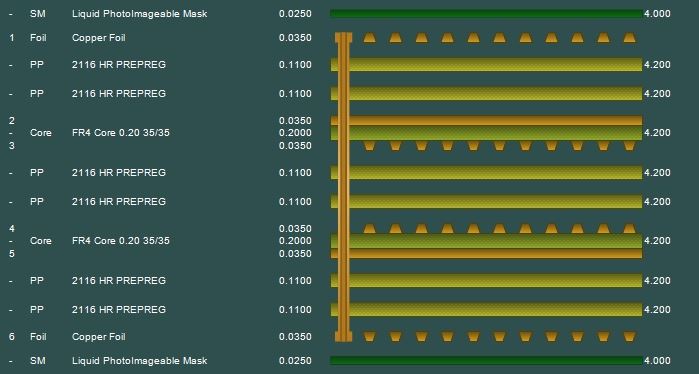

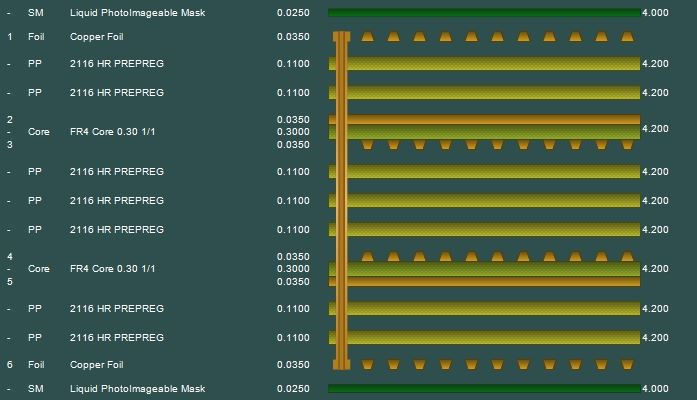

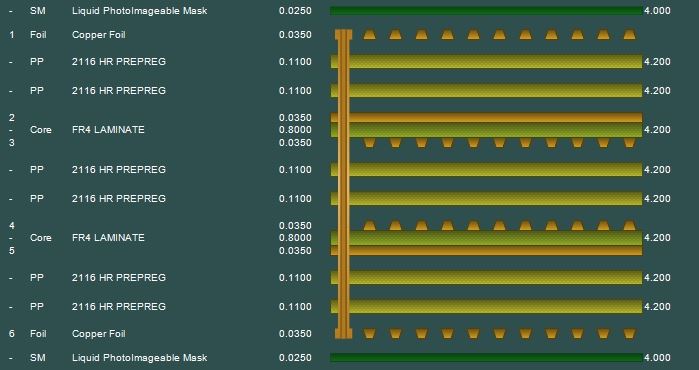

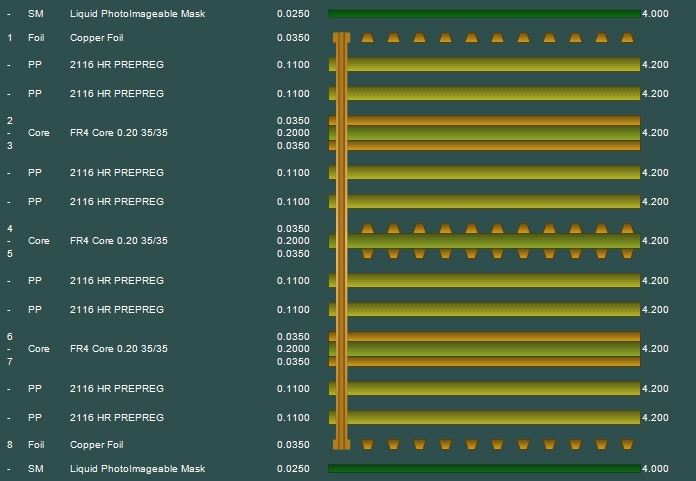

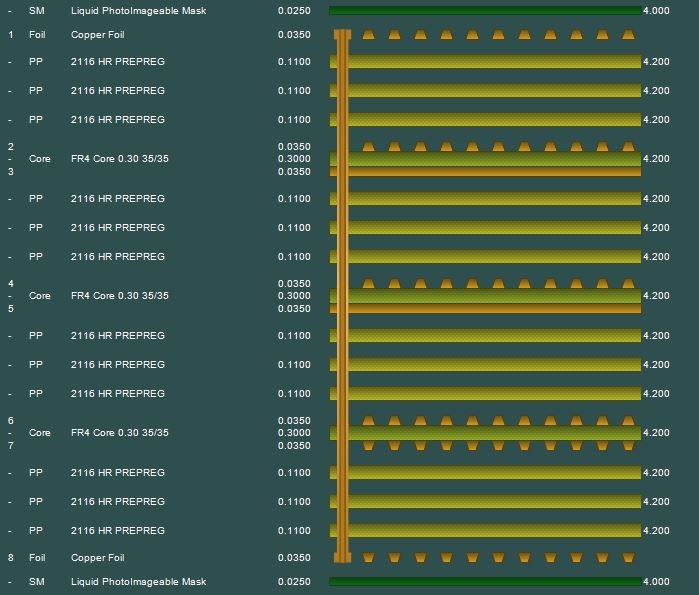

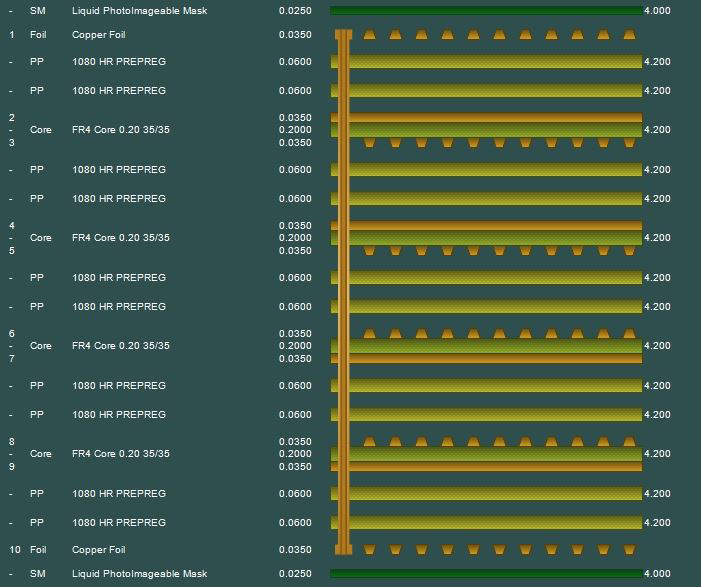

Newbury Electronics builds printed circuit boards with layer counts from 1 to 12 layers. The graphics below show the standard recommended builds of our multilayer printed circuit boards, which come in 4 layer, 6 layer, 8 layer, 10 layer, and 12 layer configurations.

For online quote and order of standard build multilayers, go to www.pcbtrain.co.uk .

If your multilayer build construction is non-standard, or the layer count exceeds 12, send us specific details of the build and we will quote. Complete a quote form to get pricing.

For more information, call our PCB experts on 01635 40347 or email info@newburyelectronics.co.uk today.

PCB