NE PCBs integral part of agricultural sector – 10 year partnership with Tillett & Hague

Tillett & Hague develop and manufacture complete control systems for installation in agricultural machinery that provides farmers with the very best in precision guidance. Farming, like every other sector, is striving for improvements in efficiencies and one means of achieving greater yields is if the farmers have a better understanding of their land and are able to ensure that every square meter is used to its best advantage.

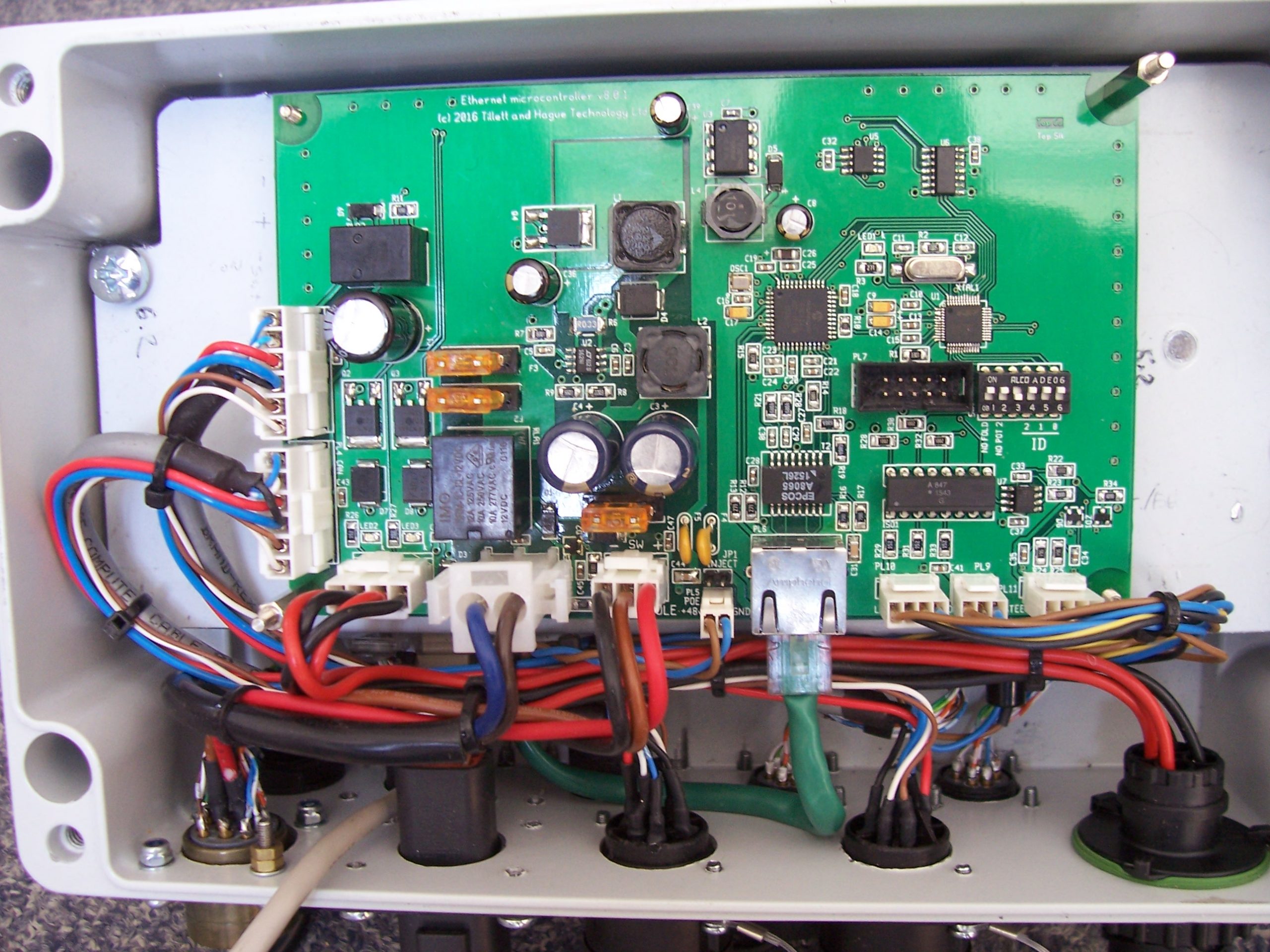

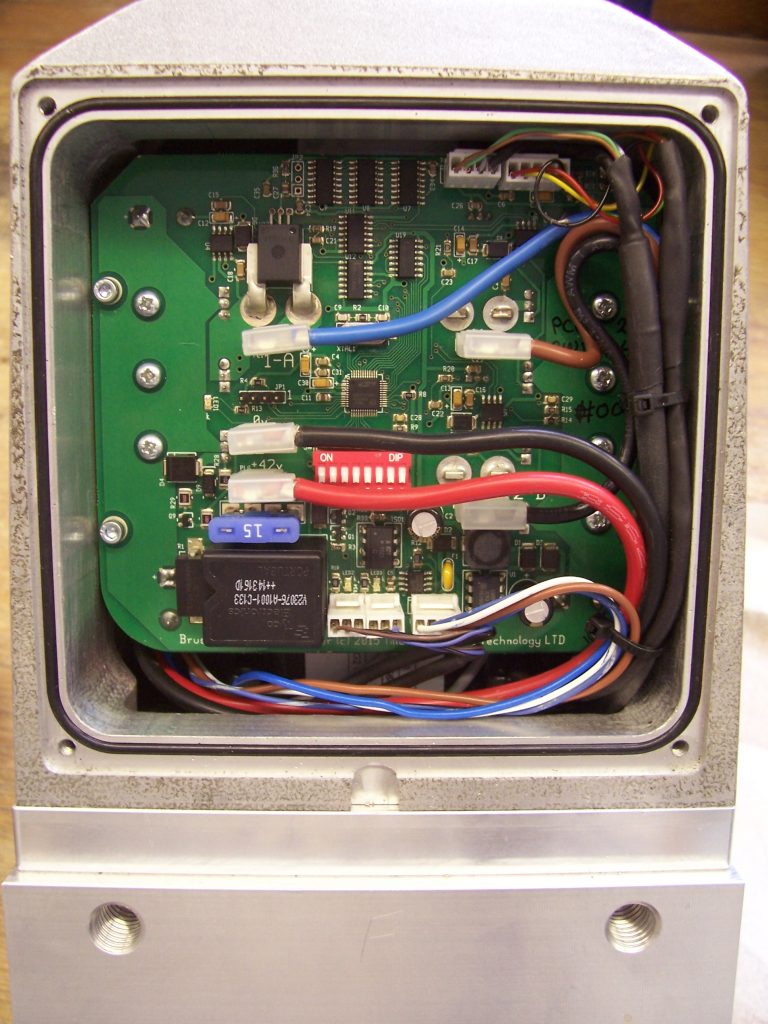

"One of our newest and most complex machines has rotary cultivators which utilised electrical drives. This machine has about 25 PCB's made by Newbury Electronics, one per rotor and several others for lateral and height control, power regulation etc. Engineering this system was quite a challenge, especially the electric rotor drives because the machine is used in an area where there is a lot of bog oak - submerged remains of ancient trees - which give quite a shock load to the cultivators when you find a lump!"; explained Tony Hague, director at Tillett & Hague.

He continued; "Newbury's solder joints have certainly stood up to the rough terrain test and the company has also been able to supply us with bespoke shaped boards enabling us to fit the controls around the motor in a cast metal housing. For the user console, the ability to integrate all the functions we need - power supply and management, touch screen control etc on the one PCB, physically shaped to fit has allowed us to make a compact, lighter and cleaner looking unit. Also important is the fact that it has allowed us to eliminate many interconnections making for quicker assembly and improved reliability."

Newbury Electronics has been supplying prototype boards and then the follow up batch production boards, usually 50 at a time, to Tillett & Hague for over 10 years. "Newbury's PCB Train service is ideal, we can get a prototype bare PCB made quickly, reliably and with little intervention," commented Tony Hague. The boards are fabricated and assembled using parts procured to a Bill of Materials supplied to Newbury by Tillett & Hague.

You can see one of Tillett & Hague's machines in action here.

Background

Tillett & Hague design and make agricultural machine vision guidance systems, primarily for weed control. The most common systems are for inter-row hoe guidance, where the system locates rows of crop and controls the lateral positioning of a tractor mounted hoe to cultivate between crop rows. More complex systems include control of rotary cultivators which are synchronised with the passing crop plants to achieve cultivation between plants in the row. Other systems control spray nozzles to target crop or weed. The company supplies the electronics and licenses the software, and work closely with its customers, principally Garford Farm Machinery, who build the machinery it controls.

Newbury Electronics Ltd has been trading for nearly 60 years, during which time it has kept in step with changes in both electronics and manufacturing. It now offers its customers some of the most advanced contract electronic manufacturing (CEM) solutions available in the UK. Philip King became MD in 2011, and has overseen over £2m of capital investment in the last 5 years. The company provides a full electronic design, and PCB CAD layout service alongside PCB manufacture and assembly in Newbury, West Berkshire. It employs over 70 staff and is dedicated to the rapid manufacturing of small and medium batch PCB assemblies. Production includes SMD, SMT, surface mount, BGA, through hole, box build, soldering, test, & rework and videos showing the various processes can be viewed here.

Newbury Electronics Ltd has been trading for nearly 60 years, during which time it has kept in step with changes in both electronics and manufacturing. It now offers its customers some of the most advanced contract electronic manufacturing (CEM) solutions available in the UK. Philip King became MD in 2011, and has overseen over £2m of capital investment in the last 5 years. The company provides a full electronic design, and PCB CAD layout service alongside PCB manufacture and assembly in Newbury, West Berkshire. It employs over 70 staff and is dedicated to the rapid manufacturing of small and medium batch PCB assemblies. Production includes SMD, SMT, surface mount, BGA, through hole, box build, soldering, test, & rework and videos showing the various processes can be viewed here.

Customers can select from any of the company’s services and the company is happy to undertake single, bespoke projects through to the design and supply of manufactured lots exceeding 10,000 pcs on its nine automated SMD assembly lines. It has recently introduced an economical express same day PCB manufacturing service for orders placed before 9am.