UTILITIES – Not always the first thing you think of with PCB Manufacture

??Water ? ?

High quality PCB fabrication requires a lot of very pure water.

Tap water is not pure enough.

For many years we have used an ion exchange demineralisation plant which required large quantities of sulphuric acid and caustic soda to regenerate the ion exchange resins.

We have replaced this with a reverse osmosis system.

This forces water through a membrane that removes impurities, leaving behind clean water.

The membrane is periodically cleaned by pressure backwashing.

The plant is much smaller, and eliminates the need for hazardous chemicals, storage tanks, and resin exchange towers.

We get cleaner water at lower cost.

All round more efficient.

Electricity ⚡ ? ?

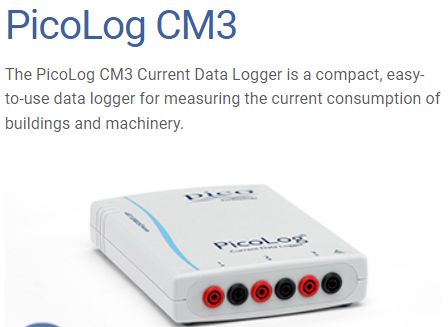

We have just installed these great little 3 phase data loggers on all our incoming electrical supplies.

Our electricity usage is now constantly monitored to an online website.

They only cost a few hundred pounds, a huge saving on professionally installed data loggers.

Our load calculations showed we had no spare headroom on our supplies.

But by monitoring the load with the Picolog's we were able to determine that we actually had plenty of spare headroom.

Because of proven load diversity, we avoided both overloads, and the need to install additional electricity supplies after installing additional equipment.