What Are Flex-Rigid PCBs?

As vital components in modern electronics, the world would be a very different place without printed circuit boards (PCBs). Since their emergence, these essentials have been relied on heavily by those who make products for various industries and they continue to evolve in terms of their capabilities.

One such development is flex-rigid PCBs, which combine the best qualities of rigid and flexible PCBs to create a comprehensive solution.

Let’s explore the differences between these three types of PCB and discover which may be the most suitable for you.

Rigid PCBs

Rigid circuit boards are perhaps the most traditional of all. They are notable for their solid structure and inflexibility, which makes them extremely durable and able to withstand high levels of stress.

As well as being used in GPS equipment and modern consumer electronics, they are equally at home in medical devices and aerospace applications. Their hard-wearing nature ensures reliability, and they have a variety of design permutations. Options here include single-sided, double-sided or multi-layered.

Rigid PCBs are low cost and suitable for devices with greater space availability.

Flexible PCBs

As their name suggests, flexible PCBs can be bent and twisted in ways that their rigid counterparts cannot. This means that they can be shaped to fit any intended system, offering greater freedom to the design.

Ideal for applications with limited space, flexible PCBs are able to flex continuously when in use. A great advantage of this is that they are guaranteed for hundreds of thousands of cycles without issue.

Lighter in weight than rigid PCBs, as well as being resistant to shock and vibration, flexible PCBs have quickly become popular options for product manufacturers.

Flexi-Rigid PCBs

A hybrid of the two PCB types detailed above, flex-rigid PCBs combine the finest qualities of rigid and flexible PCBs. Their design is a blend of rigid circuit board materials and flexible substrates, thereby achieving a solution that is greater than the sum of its parts.

Manufactured as flat laminated 2D sheets, these boards can be folded and will flex continuously to create a product with infinite applications. They also assure greater electrical performance because their circuits are integral to their overall structure.

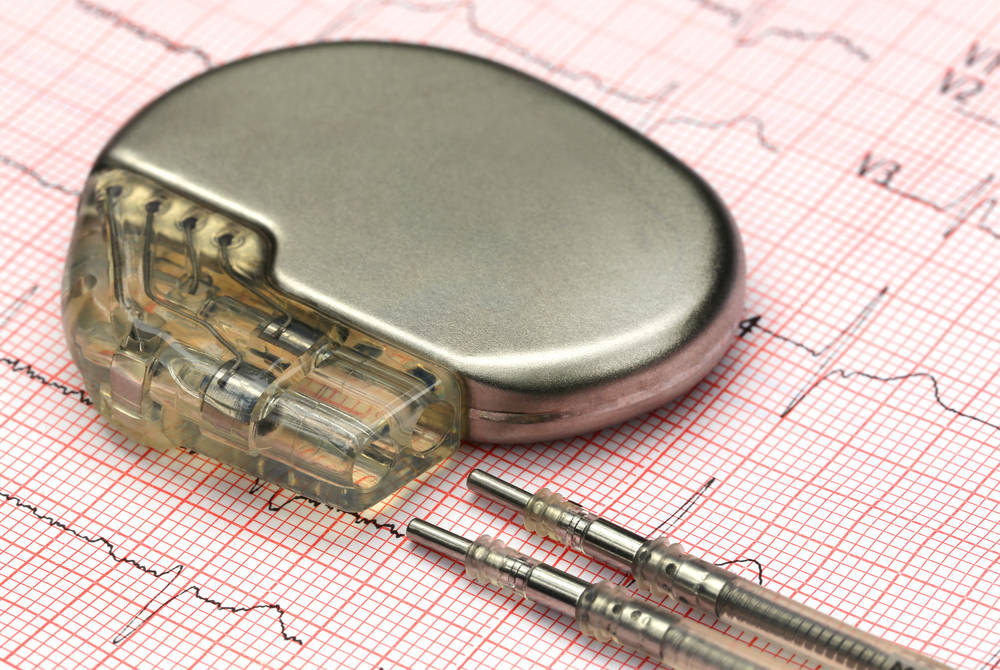

Choosing a flex-rigid PCB has many advantages. The biggest of these are a significant reduction in weight, increased reliability and greater durability. As they fold down into small, thin profiles, flex-rigid PCBs guarantee better spatial efficiency and can be used anywhere, from pacemakers to smartphones.

Flex-rigid PCBs use less material and their components can be replaced at minimal cost.

Choose Newbury Electronics For Flex-Rigid PCBs

At Newbury Electronics, we are a leading UK PCB manufacturer and have over 60 years of industry experience. We specialise in the fabrication and assembly of all types of circuit boards, including flexible and flexi-rigid PCBs.

If you wish to place an order after reading this blog, then please contact us for a quote. Should you have any questions about which type of PCB would be best suited to your needs, feel free to call us on +44 (0) 1635 40347 or email info@newburyelectronics.co.uk today.