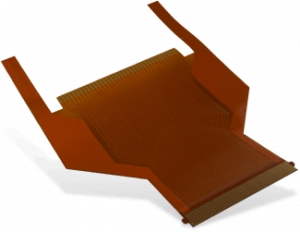

Specialists in Flex PCB Manufacture and Supply

A flexible printed circuit board, otherwise known as a flex circuit or FPCB, is a type of circuit board designed to be bent, folded, or twisted. This flexibility means that they are sometimes preferred over rigid PCBs, with many advantages, including reduced weight, improved heat dissipation, and the ability to fit into tighter spaces, giving them an edge over their more traditional counterparts.

With over 60 years of experience, our professionals can create single sided, double sided (with or without plated through hole technology), multilayered or rigid-flex circuit boards tailored to your needs. We construct flexible circuits through the sequential build-up of flexible component layers, including base polyimide, copper, cover-lay, and stiffeners, bonded by an adhesive layer (epoxy or acrylic), to create the perfect design.

Whichever type of flexible or flexi-rigid PCB you require, our engineers will help you achieve your vision. Our flexible PCBs are available in various turnaround times, depending on the type and volume you require. Send us your specification to receive a free quote today.

What technology and machinery is used?

We use a wide variety of specialist process equipment to manufacture flexible PCBs. These include laser direct imaging, ink-jet printing, flying probe testing, direct metallisation lines, vacuum lamination presses, small hole drilling machines, and integrated strip-etch-strip lines.

Do you still have a question?

Read Our FAQs View our fabrication plant