Aluminium Based Copper Clad PCBs

This type of PCB is also called aluminum base, aluminium PCBs, aluminum clad or backed, insulated metal substrate (IMS), metal clad (MCPCB), or thermally conductive PCBs.

This type of PCB is also called aluminum base, aluminium PCBs, aluminum clad or backed, insulated metal substrate (IMS), metal clad (MCPCB), or thermally conductive PCBs.

Aluminium based PCBs are best suited to single sided PCBs because of the impracticality of manufacturing plated through holes through the metal base material. For more information or advice, get in touch with our experts. Call us on 01635 40347.

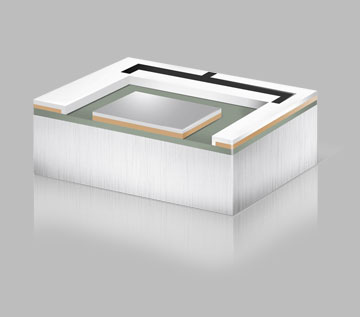

For a typical metal based single sided PCB, the base laminate is made up of copper foil bonded to a thin, thermally conductive insulating dielectric which is in turn bonded to a thick metal base, usually aluminium. The copper layer is processed in the normal way to create the tracking layer, and the profile is machined to the required shape and size. The aluminium substrate must be protected from the etching chemicals during the manufacturing process. The material is particularly suited for population with surface mounted devices. Though hole components are not appropriate because the metal base material is not an insulator. We offer single sided metal clad PCBs as standard.

![]() Greatly improved heat dissipation without using external heat-sinks

Greatly improved heat dissipation without using external heat-sinks

![]() Very mechanically rigid base laminate

Very mechanically rigid base laminate

![]() Dramatically reduce thermal stress on components, improving reliability and MTBF Relatively low cost

Dramatically reduce thermal stress on components, improving reliability and MTBF Relatively low cost

![]() Improved heat transfer allows thinner base copper and thinner tracking for high current designs as compared with standard FR4 laminate PCB construction

Improved heat transfer allows thinner base copper and thinner tracking for high current designs as compared with standard FR4 laminate PCB construction

![]() Better thermal management permits closer component mounting and smaller PCBs, yielding overall cost savings

Better thermal management permits closer component mounting and smaller PCBs, yielding overall cost savings

Aircraft landing lights

Cabin mood lighting systems

Camping gear

Automotive dashboards

Display boards

High power flash lights

Signal beacons

Power converters

Power supplies

Power transmission systems

Power distribution products

High power scanning technology

Ignition systems

Interior lighting

Landscape lighting

Medical operating theatre lighting

Room lighting

Automotive running lights

Spotlights and general lighting

Street lighting

Traffic control lighting

Tail light assemblies

There is a wide variety of this type of laminate available. To allow us to offer fast turnaround deliveries, we hold stocks of the type listed below:

| Aluminium thickness: | 1.5mm |

| FR4 dielectric thickness: | 100 micron |

| Copper thickness: | 35 micron |

| Overall thickness: | 1.635mm |

| Thickness tolerance: | +/- 10% |

| Sides of copper: | single |

| Thermal conductivity: | 2.0W/mK |

| Flammability rating: | 94V0 |

| UL file number: | E206580 |

Our standard finish is white solder resist, black legend and immersion silver. Other finishes are available.