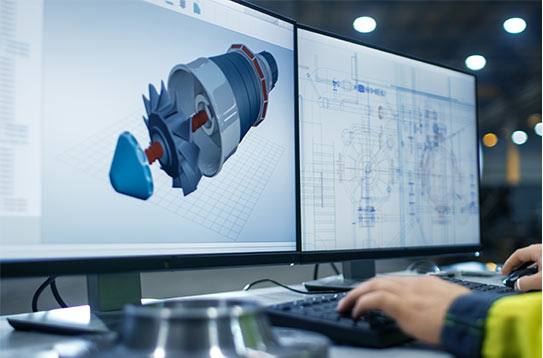

Contract Electronics Manufacturing Services

Newbury Electronics provides the most comprehensive in-house Electronic Manufacturing Service (EMS) in the UK. With extensive in-house capabilities and state-of-the-art facilities, we offer best-in-class support with electronics design, PCB fabrication, PCB assembly, box builds, and more. We are proud to be one of the UK’s best-equipped Contract Electronics Manufacturers (CEM), and specialise in helping some of the world’s leading businesses minimise costs, improve quality, and streamline their production processes.