Common Questions About: Flexible Circuits

Flexible Circuit FAQs

Newbury Electronics answer frequently asked questions about flexible printed circuits.

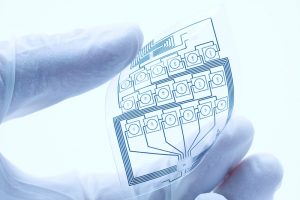

What is a flexible circuit?

Also known as flex circuits or flexible electronics; they are thin and lightweight electronic circuits usually constructed with polyimide plastic substrate.

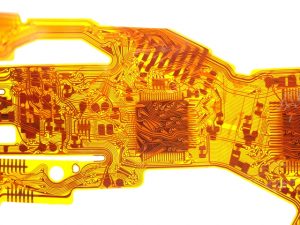

What materials are they made from?

Our flexible circuits are made from a build up of component layers; polyimide, copper, coverlay and stiffeners. These are all bonded together through either an epoxy or acrylic adhesive.

How are they different to rigid PCBs?

Traditional PCBs and Flexible PCBS serve the same purpose so many manufacturing components are the same. Similar tools and technology are used during fabrication and steps relating to the drilling of holes, printing and more apply to both boards. So which type you choose will depend on your application. When the total weight, portability or design space of a device is in consideration, a flexible circuit enables product manufacturers to configure electrical layouts in ways that rigid PCBs cannot.

What are the benefits of a flexible design?

With a flexible circuit you can design your electronics to fit your product, not your product to fit your electronics. A flex board can bend during use, allowing for greater design considerations and wiring capability when working with compact devices. Because of the thinness of the materials used, flexi PCB’s weigh less than a rigid PCB. Reliability is improved through the flexible printed circuit board having a reduced number of interconnects, meaning fewer solder joints and contact crimps.

How much do they weigh?

Flexible circuits weigh less than rigid PCBs yet still offer the same reliability and durability. A lightweight and flexible circuit board can ensure that a smaller product doesn’t increase in weight during manufacturing. A typical flex may be only 100 microns thick whilst the thinnest viable rigid board is around 500 microns.

Are they as strong as rigid PCBs?

In terms of strength under pressure, the flexibility and thinness of the design, flex circuits can cope with the stress of tension, weight pressure and the ability to be bent and curved. Compared to rigid PCBs in this sense it makes them stronger.

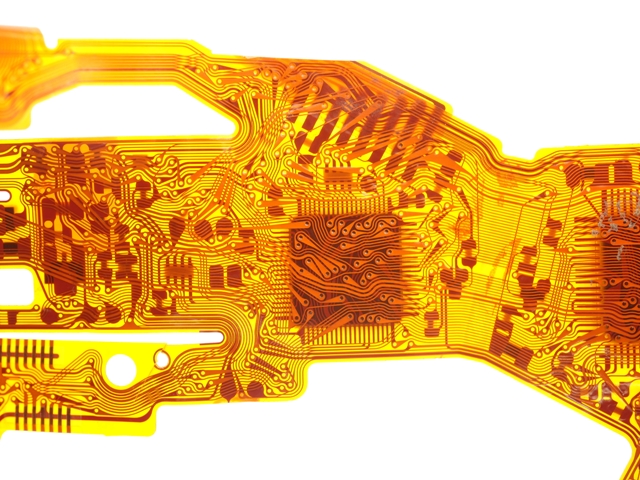

How easy is it to attach components?

If this is a feature required, the base material you select must be able to withstand solder temperatures for extra components to be attached. The region in which components are attached are generally “rigidized” because solder joints and components are not flexible, and will fail if they are not mounted on a rigid substrate. Whilst individual flex circuits can be hand assembled, to facilitate machine assembly by SMD pick and place machines, flex circuits must be mounted on or within a rigid carrier panel. Careful design for manufacture will allow simple removal of the finished assemble flex from the mother panel.

Are flexible circuits more expensive than rigid PCBs?

Generally speaking, rigid PCBs cost less than flexible circuits. Be prepared for small runs of flex circuits to be considerably more expensive than a rigid PCB of the same size. Higher volume production run will see prices converging on pricing only a little more than rigid PCBs. However, in terms of costing the whole product you’re creating, it could work out more cost effective to use a flexible PCB rather than having to edit, change and construct new ways of incorporating a rigid PCB. Flexible electronics can reduce the need for a number of components from a design and so the cost of materials and assembly overall can be reduced.

Do you have multiple manufacturing options for flexible electronics?

We use a variety of specialist processes to manufacture flexi PCBs. These include direct imaging, flying probe testing, ink-jet printing, direct metallisation lines, small hole drilling machines, vacuum lamination and integrated strip-etch-strip lines. All of these processes combined help us create the highest quality product.

Request a quote today

Newbury Electronics has vast experience manufacturing and supplying flexible circuit boards in the UK. Send us your specification today and get a free quote. Complete our contact form or email us at info@newburyelectronics.co.uk.

Read our page about Flex Manufacturing Options for more information and technical specifications.