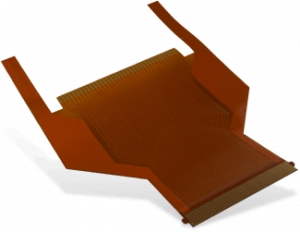

Flexible PCB and Flexi-Rigid PCB

Our capability includes single sided, double sided (with or without PTH), multi layer and flexi-rigid. All of our flexi circuits are constructed by building up component layers, eg. base, copper, coverlay, stiffener. Our flexible PCB’s are available at varying delivery times, depending on PCB type. Send your flexi-circuit PCB specifications to us by fax or e-mail for a quotation.