PCB Failure: The Most Common Reasons

These days, printed circuit boards (PCBs) are present in almost every electronic device. They help to power everything from smartphones to high-tech medical equipment, which means that their failure can be both inconvenient and catastrophic.

Yet, in spite of how irritating failure can be, there are many potential reasons for the breakdown of a PCB, from issues created during fabrication and assembly to those that occur as part of day-to-day operation.

Here’s what to look out for and what you can do to prevent PCB failure.

Fabrication And Assembly Errors

A good PCB manufacturer will have processes in place to head off failure at the early stages of PCB design. But this is not always the case.

For example, if the humidity of the manufacturing environment is not controlled, this can cause issues with how the solder and board components behave during the assembly process. As a result, components may not connect to the board in the correct way and it won’t function effectively. Common soldering issues include tombstoning, where a component is disconnected at one end, and component shifts in which a component becomes misaligned and settles in the wrong place.

Inexperienced technicians may also place traces too close together, which can lead to a slew of issues. Improper component spacing exposes the board to unbearable thermal stress, severely impacting the performance of the PCB’s components and compromising its overall functionality. This can largely be mitigated through regular training, testing and quality control processes.

In addition to avoiding human error, care should also be taken to ensure the cleanliness of the production machinery and the room in which it is contained. If this isn’t done, the PCB can become contaminated by hair, dust and other types of foreign debris. It goes without saying that this can be devastating to future performance.

One of the easiest ways of reducing contamination is to request both surface finishing and conformal coating as part of the manufacturing and assembly process of your PCB. It could save you a lot of time and money in the future.

PCB Failure Due To Environmental Factors

It’s not just a poorly managed production environment that can cause problems for PCBs. Once manufactured and assembled, they may fall victim to a host of environmental factors as part of their regular operation.

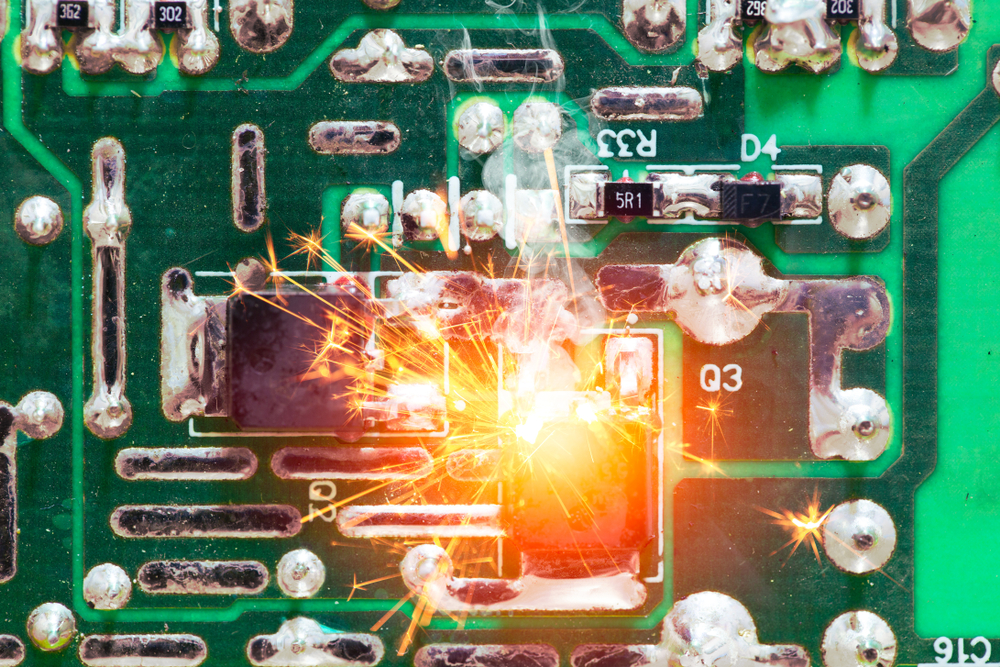

Perhaps the most common of these environmental factors is heat. PCBs generate (and are exposed to) heat on a daily basis, so may become compromised if proper precautions haven’t been taken. How a PCB can be affected by high temperatures will differ depending on the materials that have been used to put it together. In some cases, changes in heat can crack solder joints and substrate materials, particularly if a PCB has been assembled via surface mount technology. This shows there is still some value in using through-hole components.

Other environmental factors that may lead to PCB failure include exposure to moisture, dust and physical shock. Each of these things can cause a PCB to overheat and may contribute to a reduced lifespan. As mentioned earlier, there are many ways in which contamination can be protected against, such as the use of conformal coating. It is also recommended that you choose the appropriate materials and components for your PCB to mitigate these risks even further.

Age-Related PCB Failure

Whilst it may be easy to minimise chances of failure by adhering to best practices for PCB assembly and committing to appropriate component selection, there is only so much you can do to prolong the lifespan of something with a designated shelf life. Over time, particular components will naturally begin to degrade and deteriorate, creating wider problems with the function of the board as a whole.

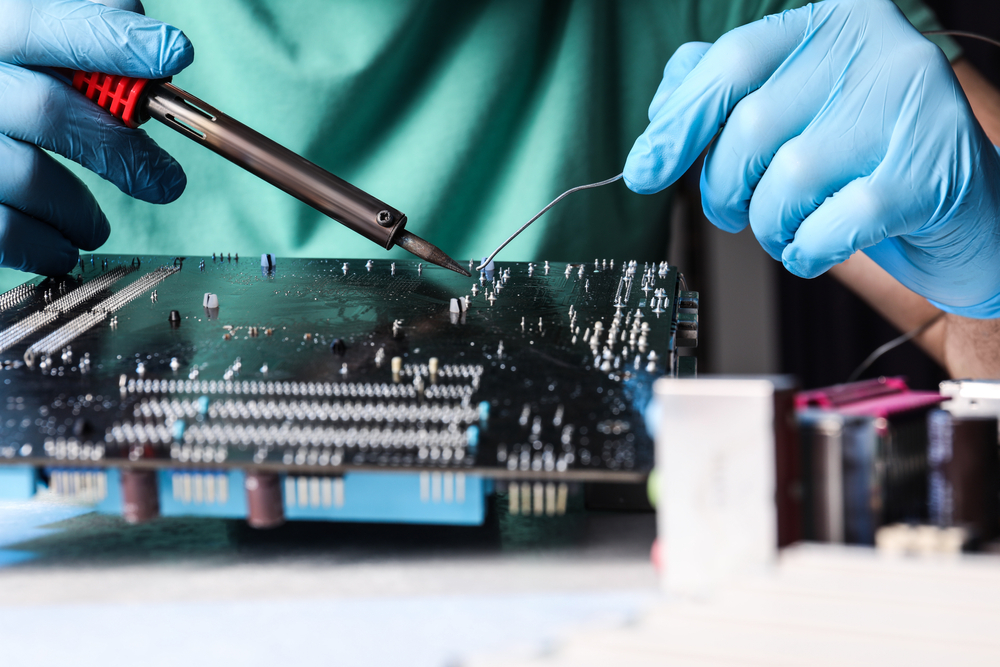

What you can do to counteract this is to have failing components replaced for a fraction of the cost of manufacturing a PCB from scratch. This is far more economical than ordering a full replacement and will extend the lifecycle of both your PCB and the product it is charged with powering. Just make sure you’re aware of your PCB’s limitations, so you know which component will need to be switched out and when.

PCB Fabrication At Newbury Electronics

At Newbury Electronics, we offer a complete PCB fabrication and assembly service. Our industry experts have countless years of experience in the creation of high-quality PCBs for a wide range of clients and applications, using the best techniques and technology to guarantee performance and efficiency every time.

To find out more about what we do, please get in touch with us today.