Converting Existing Leaded Component PCB’s to Surface Mount

[vc_row][vc_column][vc_column_text]We are being asked more and more if we can take existing leaded component PCB's and convert them to surface mount.

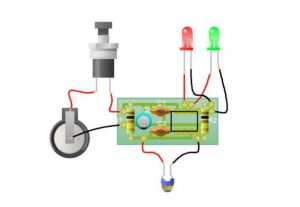

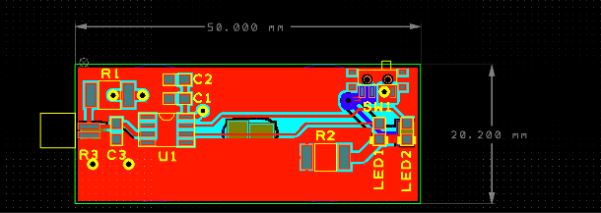

The image below shows a simple example of this. The first image is the original PCB design with leaded parts. Leaded assembly has its place, especially in low volumes. There is no machine set up time for instance. However, the availability of skilled hand assemblers within Europe is becoming limited and achieving consistent quality is also problematic.

There are many advantages for replacing leaded parts with surface mount technology (SMT).

- Normally SMD (surface mount devices) components are much smaller in size and therefore free up so much more board area which is great when adding new design / functional options. So, no increase in board size which means you don’t need to change the packaging.

- SMD components can be machined placed, reducing assembly cost.

- Because there are now no component legs poking through the PCB it frees up the underside area of the board providing more space for additional component placements.

You can see from the image above the LED’s and switch are mounted on the top side of the board. SMD coin cell battery holders are now mounted on the underside of the board. All components are now SMD saving time and money when manufacturing in volumes greater than around 1000 to 2000 pcs. Quality will be considerably better with SMD assembly too.

We are happy to take a look at your leaded design and assess the economics of a redesign in SMT.[/vc_column_text][/vc_column][/vc_row]